A Self-Guided Tour of Rock Island Arsenal

Ordnance Tour

The first ordnance stationed on Rock Island Arsenal arrived in 1816, with the establishment of Fort Armstrong. These batteries were in place to control navigation on the upper Mississippi River. Upon the resolution of the Black Hawk War in 1832, Fort Armstrong was repurposed as a weapons depot. A large swath of land was maintained through the 1860s to hold unused and stored cannon.

One of the staple products of the arsenal during World War I was the recuperator and carriages for French 75 mm guns. Subsequent needs of the U.S. military culminated in continued development to include the M101 Howitzer, the M198 field gun, the M119 howitzer, XM70 Rocket Launcher, the Nike Missile Program, and the Stryker.

This guide will help you navigate through the assorted artillery pieces on display at Rock Island Arsenal.

Important Reminders

- The U.S. Army does not endorse nor recommend any third party applications for the purpose of this tour and is not responsible for any license that the user may enter with the developer upon the agreement to install.

- Please remember that Rock Island Arsenal is an active military installation. Note that some points on this tour can only be viewed from the outside and some can no longer be seen. Other points have regular business hours. Be security aware and do not wander into restricted areas or locations that are off limits.

- Remember to obey traffic laws and obey posted signage.

- Use of a mobile device while you are driving is strictly prohibited.

- For your own safety, and the safety of the artifacts, please do not climb on any macro artifacts that are shown on this tour.

- Pictures are allowed north of Rodman Ave.

To get started on the tour, click one of the tour or interest points on the left or in the menu above (depending on your device). The number corresponds to the point of interest on your tour sheet.

If you do not have a copy of this self-guided tour, you can do so by clicking below.

« Return to Tour Data Page

« Return to Virtual Tour Page

« Return to History Office Page

| M115 203-mm Howitzer |

Click on an image to view a larger version |

Originally designated the M1 8-inch howitzer, then the M115 8-inch howitzer before becoming standardized as the 203-mm howitzer, the M115 was the United States’ standard heavy howitzer used during the Korean and Vietnam Wars. Design of the gun began following the close of World War I and arose from the need of the U.S. Army’s reliance on British artillery in the war. After numerous program setbacks from 1920 to 1939, it finally entered production in 1942.

Despite having been produced in time for World War II deployment, its fielding was relatively small, requiring specialized tractors to move. Mobility was improved in the 1950s to make it better maneuverable by its prime mover. The M115 had two different carriages. The more agile of these was the “triple threat” carriage, which was used for 175-mm and 155-mm guns in addition to the 203-mm tube.

The ”8-inch” and “M1” nomenclature was used through 1962, when the Army adopted the first of several nomenclature standardization policies. Following this, it became known as the M115 203-mm heavy howitzer, tracked.

Starting from 1957, the M115 was adopted by multiple NATO armies for multiple purposes. Chief among them was the deployment of atomic artillery for deterrence under the NATO nuclear sharing concept. The M115 could fire the M422 shell which carried a W33 which could yield up to 10 kilotons. It was later able to fire shells with the W79 one kiloton warhead. The atomic role ended in 1992 with the Treaty on the Non-Proliferation of Nuclear Weapons (also known as the non-Proliferation Treaty (NPT)). Despite its capabilities, it never fired an atomic round.

More commonly, the M115 was used by NATO nations in other conventional engagements. This included the Second Taiwan Straight Crisis, the Iran-Iraq War, and Operation DESERT STORM.

In addition to its role as a towed howitzer, a few attempts were made to fit the M115 to self-propelled chassis. The two most successful attempts were the M43 and later the M110 and M110A2. The M110A2 was used by the United States until 1994.

This specific howitzer that is located at Rock Island Arsenal’s Memorial Field has a unique history associated with it. In 1977, the howitzer was overhauled at Rock Island Arsenal before being shipped to Iran. During the Iran-Iraq War, it was captured by Iraqi troops. The Iraqi Army then used the howitzer against Coalition Forces during DESERT STORM in 1991. The howitzer was then captured by the U.S. forces before being shipped back to Rock Island Arsenal for overhaul and restoration. It has been displayed at Memorial Field ever since.

The M115 remains in limited service with various nations around the world. |

| » Fact Sheet « | » More Stories « |

The first 130-mm field gun produced by China was the Type 59-1, a copy of the Soviet M-46. It fires high explosive and illuminating projectiles. The gun is towed by a 6x6 truck and is served by a crew of eight to 10 soldiers.

The original M-46 was developed from the Soviet M-36 naval gun designed for coastal defense. The design of the gun began after World War II, with the first units being fielded shortly after the Korean War began. When it was produced, it had one of the longest effective ranges in the world, at 17 miles unassisted and over 23 miles assisted. The first public display of the M-46 occurred at the May Day Parade in Moscow in 1954.

The Type 59 was one of 10 variants that were produced by countries outside of the Soviet Union. The Chinese-built Type 59 was the licensed version; two modified versions were later built by the Chinese. The Type 59-1 was the lighter variant, weighing 1.4 tons less than the M-46. The GM-45 was the exported version of the Type 59. The lighter weight of the 59-1 was accomplished by using a lighter carriage that was designed for the Type 60 (D-74) - a smaller towed gun also from the Soviet Union.

The M-46 has variants associated with Cuba, Egypt, India, Israel, North Korea and Serbia. The weapon remains in service with many countries in Asia and Africa, including Iran, Iraq, Pakistan and Thailand.

The Type 59-1 displayed at Memorial Field is a lightweight Chinese variant that was sold to Iraq. It is one about 675 guns that were in the Iraqi inventory during Operation DESERT STORM. The weapon was recovered by the Center of Military History and shipped to Rock Island Arsenal in 1992.

| M4A3 Sherman Tank |

Click on an image to view a larger version |

Design of the M4 Sherman can be traced back to the development of the 1935 M2 light tank, which in of itself was derived from infantry design from the 1920s. Between 1935 and 1940, multiple iterations of tank were designed with a handful produced. The M4 was explicitly designed to replace the stopgap M3 tank, which featured a smaller gun system. Once a larger mount could be devised, the plan was to replace the M3 with whatever weapon system was to come. Thus, the development of a turret mount for a 75-mm gun resulted in the design and production of the M4 Sherman Tank.

The M4 Sherman was a culmination of over 20 years of U.S. Army research on perfecting tank design. This included later iterations such as the M4A2, A3, A4, and A6 variants. The modular design of the platform enabled easy modification and upgrading of components on the system. Because of this, the M4 saw over 50 different variants and a wide array of mission capabilities that far exceeded the original production intention. This included three different gun barrels on these models, with 75-mm, 76-mm, and 105-mm tubes being used. However, the 75-mm tube that the platform was designed for remained the most used.

Other M4 Sherman modifications included anti-personnel systems (including mines and flamethrower turrets), rocket launchers, artillery tractors, recovery tanks, engineer tanks, and self-propelled howitzers.

The M4 remained in U.S. service through the Korean War, eventually being replaced by the M47, M48, and M60 Patton series of tanks. However, many Sherman tanks remained in other Ally possession following the close of World War II. In addition, the M4 Sherman was exported to many NATO nations and international partners. This included licensed Sherman tanks produced by Britain, many of which went to Paraguay. Many American produced Sherman tanks were sent to Israel where they remained in service through the 1973 Yom Kippur War.

The last Sherman tank was removed from service in 2018, when Paraguay removed them from their inventory. This ended a life of service of 78 years.

The Sherman on display at Rock Island Arsenal’s Memorial Field is an M4A3 variant. Many of these tanks were produced by the Ford Motor Company and were powered by a 500 horsepower Ford V8 engine. It was considered one of the most reliable of the Sherman variants and featured enhanced armor that increased survivability. Many of the M4A3 variants utilized either the 75- or 76-mm tube, with the larger M4A3E2 Sherman Jumbo’s also having thicker armor. A total of seven M4A3 configurations existed in the U.S. arsenal, making it the largest family of configurations for the tank. Of all the different variants of M4, the M4A3 was the preferred design of the U.S. Army.

The yellow marks on the tank represent individual locations where the system was struck by enemy fire. Studies were conducted on Sherman tanks, much like B-17 bombers, to assess where armor was most needed to increase survivability. This Sherman received damaging blows to its tread gears and the turret, effectively putting it out of service. |

| » Fact Sheet « | » More Stories « |

| M50 Ontos |

Click on an image to view a larger version |

Designed to be an air-deployable tank-destroyer, the M50 Ontos designed in the early 1950s. It was an evolution from the M56 Scorpion that had been designed in the late 1940s. Limitations in payload of early transportation aircraft meant that the design envelope for Ontos was relatively limited. It could not exceed 20 tons in weight. To accomplish this, a lighter engine was necessary thus, unlike many other self-propelled systems, Ontos used a V6 engine. The U.S. Army ordered 297 of these gun systems in 1955, however issues that plagued the Ontos were so great that the Army cancelled its order. However, the Marine Corps subsequently purchased all 297 vehicles instead.

The largest obstacles for Ontos were the inability to carry a meaningful load of ammunition, the extreme backblast of the recoilless rifles, high profile, and the need for exterior reloading of the guns. These were the primary reasons that the Army cancelled their order.

The M50 is a unique and imposing creation distinguished by its six M40 106-mm recoilless rifles. All six of these guns required the loader to exit the safety of the armored covering of the vehicle to reload them. This exposed them to enemy fire in extreme conditions. The M40 rifles were manufactured by Watervliet Arsenal and despite their description as a 106-mm gun, they were 105-mm in caliber. The change in the nomenclature was designed to prevent confusion with incompatible 105-mm ammunition of the obsolete M27 recoilless rifle.

Allis-Chalmers manufactured all 297 Ontos and based the on the chassis for the M56 Scorpion anti-tank gun. The engine was a six-cylinder GMC engine that was commonly used in Army troop transport vehicles and trucks. Early models were much more limited in motion and movement than the later M50A1 variant. The differences between the original M50 and M50A1 included a more mobile turret, improved suspension, and more resilient tracks. However, both variants were still constrained by payload requirements. Because of this, each could only hold approximately 18 rounds of 105-mm ammunition.

In addition, four of the M40 rifles featured M8 spotting rifles to assist with aiming the 106-mm guns. An M1919A4 .30 caliber machine gun was also installed for anti-personnel application. This made the weight envelope much more constrained despite its impressive appearance.

The M50 saw limited combat action in Vietnam. Its role as an anti-tank gun was stifled by the lack of tank deployment by the North Vietnamese Army. It was instead used as artillery support in fortified positions due to poor armor. However, for all its faults, it was a capable artillery system, capable of traversing on paths that other larger artillery could not. It could also provide intense immediate firepower, which reportedly made it a formidable and sometimes imposing element on a battlefield. The M50 also saw limited anti-tank weapon use during the American intervention in the Dominican Civil War. By 1969, however, all M50s were deactivated.

Of the 297 built, only about 15 remain today, most of which are the M50A1 variant.

A stand-alone M40A1 Recoilless Rifle is on display at the Rock Island Arsenal Museum. It is coupled with a Rock Island Arsenal produced M8C spotting rifle with an M79 mount - the standard mount that was used for the stand-alone gun. |

| » Fact Sheet « | » More Stories « |

| M51 Skysweeper |

Click on an image to view a larger version |

World War II paved the way for numerous new technologies in the battlefield. Chief among these was jet aircraft. Following the close of the war, it was determined that new technology would be needed to fill the role of the anti-aircraft mission that was capable of meeting jet powered aircraft in the skies. While the Bofors had effectively covered low altitudes and slow speeds and more power flak-guns covered the high altitudes, the middle altitudes and higher speeds at low altitudes proved difficult. Thus in 1948, development began on a weapon system to fill this hole in air defenses.

The changing nature of aviation coupled with technological scares following the close of the war and the increase in global tensions expedited the need for airspace security. The successful supersonic flight of the Bell X-1 and the altitude capabilities of the Convair B-36 Peacemaker left reason to believe enemies were not far behind with similar specifications. Larger guns could cover the high altitudes, but the middle-altitudes between 20,000 and 40,000 feet was poorly defended. The anti-air systems below 20,000 feet were also poorly equipped to handle high-speed aircraft.

Officially designated at the Gun, M51, Anti-aircraft, the M51 Skysweeper was designed to handle aircraft cruising at speeds of up to 700 miles per hour and at an altitude of up to and over 40,000 feet. By comparison, at the time of its introduction in 1951, the contemporary jet fighters were the F-86 Sabre and the MiG-15 which traveled at 687 and 667 miles per hour, respectively.

The M51 was fitted with a radar system and computer that was developed by the Sperry Gyroscope Company. The M35 75-mm gun was developed by Watervilet Arsenal and was fed by two ten-round revolver magazines. The autoloader allowed it to reach up to 45 rounds per minute. The T38 radar system could detect enemy aircraft as far as 23 miles away. The system was first produced in its entirety in 1951 and fielded immediately, although it was not publicly disclosed until 1953.

However, the M51 was not designed to stay in the U.S. inventory for long. Despite its service into the mid-1970s, it was rapidly made obsolete. By the time it was announced to the public, the F-100 Super Sabre was capable of speeds of up to 863 miles per hour. Just six years later the Soviet MiG-21 Fishbed was capable of speeds over 1,300 miles per hour, making the M51 unable to keep up. In addition, the middle-altitude space was increasingly becoming patrolled by surface-to-air missile systems such as the Nike.

Most Skysweepers were removed from service by 1957, with the last in North America being deactivated in 1959. Many Skysweeper units remained overseas until the 1970s. Exports of the units were limited exclusively to NATO nations. |

| » Fact Sheet « | » More Stories « |

The Bofors was the standard anti-aircraft gun system for Allied nations during World War II. After the war, many other nations acquired the weapon system for their air defense network. At its peak, the Bofors was exported and licensed to almost 100 operators around the world. It remains in service in many nations today.

Developed in Sweden, the Bofors was a stationary to semi-mobile anti-aircraft air defense weapon. The initial production units were capable of firing over 23,000 feet, with revised variants capable of firing up to 41,000 feet. Initial production variants fired at a rate of 120 rounds per minute, while the updated versions exceeded 300 rounds per minute.

Toward the end of World War II and after, the Bofors design was licensed to both the United States and Britain. More than 25 variants were produced, with total units produced exceeding 150,000. At least 60,000 L/60 variants were produced before the war ended in 1945.

Today, the Bofors is still used in nations around the world, including the United States. Most recently, 40-mm L/60 variants have been fitted to AC-130U "Spooky II" gunships. Fitting of the Bofors to AC-130s began in 1970 with the first production AC-130A. The AC-130U is the last gunship variant to use the Bofors, and subsequent models will use a 30-mm GAU-23 cannon instead.

The D-44 85-mm antitank gun was the successor to the smaller 76-mm design used during the majority of World War II. The gun system was developed from the well-known T-34-85 tank, which used the same barrel, muzzle, and recoil mechanism as the D-44. When it was first fielded in 1945, it had the highest rate of fire of any field gun. It was capable of firing up to 25 rounds per minute.

The gun was later exported to various operators within the Soviet bloc, with virtually all Warsaw Pact nations obtaining the weapon by the late 1950s. The gun was also licensed to China, where it was rebranded as the Type 56. These licensed versions would see action during the Vietnam War in a limited capacity. Of the over 8,000 guns produced, it is estimated that 600 remain in service. Over 400 Type 56 variants remain in service as well.

The D-44 was capable of firing incendiary, high-explosive, and armor piercing rounds. The armor piercing rounds were capable of penetrating 100 millimeters of armor, with other projectiles capable of piercing anywhere from 180 to 300-mm of armor. This made the D-44 one of the most deadly field guns on the battlefield.

The gun was formally retired from front-line service with the Russian Ground Forces in the 1970s in favor of larger, more accurate antitank systems.

| M101 Howitzer |

Click on an image to view a larger version |

Originally designated as the 105-mm howitzer M2A1 on carriage M2, the M101 howitzer was the light howitzer of choice for Allied forces during World War II. Like many World War II howitzers, the M101 traces its developmental genesis to the post-World War I era. Following the close of hostilities during the First World War, research on German 105-mm howitzers developed several candidates of ordnance. A series of continued research continued various trails, carriages, and tubes before finally settling on a combination that was not only extremely accurate, but extremely powerful. Thus, by 1940, the M2A1 was born.

Designed to be durable and stable, the M2A1 rapidly gained notoriety among the Western Allies for extremely accurate and devastating firepower. It also required very little maintenance, being able to withstand great amounts of stress over time.

From 1941 to 1953, Rock Island Arsenal and Kia Machine Tool Company produced over 10,000 of the howitzers. Around 8,500 of those were produced during World War II, with the remainder being produced until 1953. Many were distributed via Lend-Lease. Many others were exported to NATO nations following the end of the war. The M2A1 continued to see American use during Korea and Vietnam.

The M2A1 was redesignated the M101 in 1962 following the standardization of artillery designations.

The M101 could deploy multiple ammunition types to include high explosive (HE), incendiary, armor piercing (AP), smoke, and chemical shells. Many of these rounds were used across multiple howitzer systems of the same caliber. The howitzer is also used in anti-avalanche measures to generate controlled collapses that can prevent risks to life, agriculture, and property.

Because of its versatility, the M101 has been the basis for numerous studies and experimental systems. Examples include the M2A2 Terra-Star and the XM124. Most experimental designs were produced by Rock Island Arsenal from 1959 to 1973.

Despite being retired from U.S. service following the Vietnam War, many other nations continue to use the M101. In some U.S. formations, the M101 is sometimes still used as a salute gun. Most recently, the weapon has been used in the Russo-Ukrainian War. |

| » Fact Sheet « | » More Stories « |

The XM123 is a modification of the M114 155-mm medium towed howitzer, also produced at Rock Island Arsenal. The XM123 was an auxiliary powered design that added an engine to the howitzer carriage to allow it to become more mobile in a limited capacity. This allowed for better defensive measures, better target acquisition, and less time to correct firing positions after fire. The XM123 base model included two 20-horsepower engines, while the XM123A1 variant included a single engine.

Extra weight on the rear of the howitzer caused the barrel to become misaligned, and as a result the overall project was terminated. However, the M123 was produced in limited quantities using the twin engine design. None of these units were ever used.

The XM123 was one of many experiments to add auxiliary propulsion to a normally towed howitzer. Other proposals included the XM124 and the Terra Star, both of which were also manufactured at Rock Island Arsenal. The XM124 utilized a smaller 105-mm barrel, while the Terra Star utilized the 105-mm barrel coupled with a tri-star wheel configuration.

Changes in the needs of the U.S. Army led to the eventual termination of these programs; as a result, most of the auxiliary powered howitzers were never produced. Most howitzers that were produced were destroyed.

Using the M101 Howitzer as the foundation for its design, the XM124E2 was the third prototype for the XM124 family. The concept was to develop a howitzer that was able to self-correct without needing a secondary prime mover to adjust its position. The XM124 provided between one- and 22-horsepower engines to drive the carriage. The engines were air cooled, and the motion of the carriage was controlled through electric steering.

The goal of the engines was not to consistently drive the howitzer from point A to point B, but rather to allow it to move small distances to correct its firing position, move into a better defensive position, or to provide a larger range of fire. The XM124 testing took place ahead of the M2A2 Terra Star testing that utilized a tri-star wheel concept in addition to self-propulsion.

The project ran from 1962 through 1965, when the project was cancelled due to lack of need for the weapon design.

The XM124E2 at Rock Island Arsenal is the only E2 prototype, having a single 20-horsepower engine and a lighter weight carriage for better mobility and better efficiency.

The weapon at Memorial Field one of 14 British L119 light guns leased to the U.S. Army in 1985 for evaluation. The system was revised by Rock Island Arsenal as the M119 lightweight towed howitzer in 1986. It was adopted to replace the M101 105-mm light towed howitzer. A total of 521 M119 and M119A1 howitzers were manufactured at RIA from 1991 to 1997. Watervliet Arsenal in New York manufactured the cannon tube and associated components. Rock Island Arsenal manufactured 1,200 parts for this system. RIA's Joint Manufacturing and Technology Center continues to support this system with parts and upgrades, including the latest A3 variant.

First developed to replace the aging M101 howitzer, the M119 is based on the British L119 howitzer. The howitzer underwent extensive research at Rock Island Arsenal, where revisions and upgrades were drafted. In the initial production run, 521 howitzers were produced. In 2013, JMTC received the contract to continue production of the howitzer. In addition, JMTC is responsible for producing replacement parts and providing upgrades when necessary.

Light enough to be airlifted and dropped, the M119 was designed to either be carried with slings by helicopter or dropped from transport aircraft. Its ability to be carried and packed so easily has made it one of the most versatile weapon systems in the U.S. Army inventory, one reason the M119 remains in service today.

There are four production variants plus the L119 model. The M119A1 includes a fire control and maintenance system, while the M119A2 model has upgraded sights. The most recent revision is the M119A3. The A3 model has a digital fire control system and an internal navigation system for self-location. The latest variant entered service in April 2013. The entire system is moved by the M1097 High Mobility Multi-Purpose Wheeled Vehicle (HMMWV). The system is capable of firing high explosive, illuminating, smoke, and long-range ammunition.

| M198 155-mm Howitzer |

Click on an image to view a larger version |

The M198 155-mm Howitzer was one of the Rock Island Arsenal’s most significant projects in modern history. The program arrived at Weapons Command’s (WECOM) Artillery Systems Laboratory in 1968 during the height of the Vietnam War. Work continued through 1977 with studies being conducted on how artillery systems fielded in the jungle fared. From 1955-onward, the U.S. Army had been heavily emphasizing the importance of sling-carried ordnance systems. The culmination of all this research resulted in the eventual development of the M198.

Following the design and development phase at the weapons laboratory (later transferred to Rock Island Arsenal as an installation function and renamed the Thomas J. Rodman Labs in 1972), the Rock Island Arsenal manufactured upwards of 1,600 complete systems.

The M198 was first fielded beginning in 1978 with both the Marines Corps and the Army. It saw action during Operations DESERT STORM and DESERT SHIELD, then again later during ENDURING FREEDOM and IRAQI FREEDOM. In addition, several NATO allies procured shipments of M198’s, including Brazil, Thailand, and Pakistan.

Designed to replace the M114 howitzer from World War II, the M198 was designed to be easily fielded and maneuvered. Its light weight – just shy of eight tons – allowed the system to be dropped by parachute via cargo transport or via sling with heavy helicopters. The primary mover of airborne deployment has been the C-17 Globemaster III and the CH-47 Chinook. The M198 was also capable of being pulled by tractors and heavy trucks, enabling rapid relocation and deployment. It could fire up to four shells per minute.

Up until the Treaty on the Non-Proliferation of Nuclear Weapons (also known as the Non-Proliferation Treaty (NPT)), the M198 was capable of firing atomic rounds. The W48 shell was one of the smallest nuclear devices that had ever been designed and produced a yield of around 72 tons. Atomic rounds were only one of the many shells the howitzer could serve as a catalyst for. In addition, high explosive, rocket-assisted, illumination, area deniability, and even seek-out shells were able to be used in this system. Despite its capabilities, the M198 never fired an atomic round and following the NPT, all atomic shells were removed from U.S. inventory.

Today, the M198 has been largely phased out in favor of the much lighter M777 howitzer. Regardless, the system continues to be used in many other NATO nations today. The Rock Island Arsenal continues to work with NATO Allies to ensure these systems are well maintained and combat ready for the future. |

| » Fact Sheet « | » More Stories « |

| M65 Atomic Annie |

Click on an image to view a larger version |

The M65 280-mm Motorized Heavy Gun, more commonly referred to as “Atomic Annie”, was the first of a generation of weapon systems designed to fire atomic artillery. The need for the M65 was defined in doctrine following the end of World War II. Specifically, it grew from the planned Ally Invasion of Japan (DOWNFALL) in 1945. Use of small tactical atomic devices were anticipated to be used alongside of standing forces. Following this, deployment of smaller nuclear devices was commonplace for two key reasons. First, it provided a means of deterrence against potential Soviet invasion. Second, it was a way to inflict significant damage to an enemy at a relatively cheap materiel and personnel cost.

When the Cold War began in 1945, atomic devices had not yet been fitted to missiles and bombs were far too heavy for most aircraft. This changed with the deployment of the B-36, B-47, and B-50, but remained an obstacle in closer quarters. Eventually, aircraft, ships, and missiles would be able to launch larger atomic devices, but the function of smaller and tactical atomic weapons fell to short range rockets and artillery. Thus, Atomic Annie found her place.

Based on the “Anzio Annie” gun developed by Nazi Germany (which was already borrowing designs from the Paris Cannon from World War I), the M65 mated multiple pieces into a single weapon system. The T131 280-mm gun was developed at Watervliet Arsenal in New York in 1950 with the intention of arming it with a projectile tipped with a W-9 15 KT warhead (T124). The T72 Gun Carriage was used to cradle the gun. The main prime mover in front of the gun was designated M249, and the one at the rear was designated M250. Both these 4x4 semi-trucks were required to move the gun into firing placement and manufactured by the Kenworth Truck Company. Study on the carriage and recoil mechanism was conducted by the Rock Island Arsenal.

The first test of the gun began in 1952 at Aberdeen Proving Grounds in Maryland. In 1953, the gun was ready to test its atomic delivery capabilities. On 25 MAY 1953, one gun was emplaced in the Nevada Proving Ground as part of the UPSHOT-KNOTHOLE atomic tests. The first and only atomic round fired from these guns was named “Grable”, and it detonated at a range of 8-miles approximately 500 feet above the target.

The gun was subsequently stationed in both the European and Asiatic theaters, seeing most of its time in Germany and Okinawa. However, some of the guns were shipped to South Korea for response testing in the event of ongoing conflict. None of the 20 guns developed and deployed were ever fired in anger. The most these guns saw of any action was firing conventional rounds down-range at firing ranges in Europe near Fulda and over the East China Sea.

Only eight of the guns produced remain today, having been quickly replaced by smaller and more maneuverable weapon systems by 1959. The gun at Rock Island Arsenal is a T131 gun mounted on a T72 carriage, like many of the surviving specimens. The only complete M65 assembly known to remain is at Aberdeen Proving Grounds. |

| » Fact Sheet « | » More Stories « |

First designed in 1939 and produced in 1941, the M114 155-mm howitzer is one of the longest-serving weapon systems ever produced. The M114 entered service during World War II as the M1. It was later designated the M114 after a reorganization of the Army's numbering system. The M114 was the standard issue 155-mm howitzer during both the Korean and Vietnam Wars. The howitzer was replaced beginning in 1979 when the M198 howitzer, also produced at Rock Island Arsenal, was introduced.

The M114 was assembled at Rock Island Arsenal from 1941 through 1953, with the carriage and recoil mechanisms produced in-house. During that time, RIA assembled more 10,000 howitzers. Many were sold to foreign operators, which numbered over 40 by 2016.

The M114 fired multiple types of ammunition, including high explosives, smoke, and chemical shells. Shells generally weighed between 90 and 100 pounds and used various propelling charges to strike up to nine miles away.

The M114 remains in foreign service with over 20 operators, accounting for around 1,000 of the units produced.

The M101 105-mm howitzer, previously referred to as M2A1, was the standard light howitzer deployed with the U.S. Army during World War II. Over 10,000 were produced, with the majority of them manufactured and assembled at Rock Island Arsenal. Production ran from 1941 through the end of the Korean War in 1953. The United States exported the weapon to over 50 countries, including some nations through the World War II-era Lend-Lease Program.

The M2A1 was capable of deploying a large assortment of artillery shells. The standard shell was a 42-pound high explosive shell with a range of just over seven miles. The howitzer was also capable of firing smoke, chemical rounds and armor-piercing rounds. Eleven variants of the gun carriage, and 12 variants of the carriage, were drafted, designed, and produced, including the M2A2 Terra-Star Auxiliary Propelled Howitzer.

From 1969 through 1977, Lockheed Aircraft Service Company and Rock Island Arsenal experimented with the tri-star wheel arrangement concept. This concept utilized an assembly of three wheels, coupled with a single spinning axle. The design was meant to act as an alternative to a track design and allow for smoother transit on paved and rough surfaces. On a smooth surface, the two bottom wheels would spin in motion, just like a typical automotive wheel. However, if the howitzer was off-road or approached a hole, the entire wheel assembly would rotate, allowing the howitzer to move beyond the obstacle with ease.

The M2A2 on display at Rock Island Arsenal is the only Terra-Star known to have survived, and it is believed that only two were ever manufactured.

The T88 rocket launcher was an experimental weapon that was designed in 1941 and built in 1942. The intent was to increase the destructive power of field-deployed rocket artillery with a larger payload and a larger rocket. The T88 itself was never put into production. However, research and development on the T88 system likely aided in the development of tank-mounted rocket systems such as the T40 Whizbang.

Tank-mounted launchers were produced in larger quantities by 1944, with the T34 Calliope fulfilling the role of the 4.5-in design. Both the T40 and T34 were mounted onto M4 Sherman tanks. The majority of the configurations included a 75-mm gun turret with a 180-degree turning radius.

Multiple types of rockets were produced for the 7.2-in launchers. These included the T37HE high explosive rocket and the T21 chemical rocket. The combination of heavy rocket fire with the use of a heavy cannon meant the entire weapon system was capable of putting down a devastating amount of fire in a short period of time. The mobile nature of the mount meant that the vulnerability of the launcher was also less than other towed systems.

Other applications of the T88 launchers included towed mounts, amphibious assault vehicles, trucks, and other landing craft. The mount displayed at Memorial Field is a towed mount design.

The Nebelwerfer ("Fog" or "Smoke Thrower") were a series of rocket-launching systems produced by Nazi Germany from 1934 through the end of World War II. The launchers were given their name as a method of disinformation to fool members of the League of Nations. Since the literal translation meant "smoke mortar" or projector, the weapon system was overlooked under the assumption it was being designed as a defensive weapon to create a smoke screen. Nine different variations of Nebelwerfer were produced, which ranged from the 100-mm NbW-35 to the 300-mm NbW-42.

The NbW displayed at Rock Island Arsenal is an NbW-41 150-mm rocket launcher.

Entering service in 1941, the NbW-41 was a key weapon used by Germany on the eastern front. It was also used in limited quantities in France and Italy. The weapon was fired via remote control and could empty all six tubes in 90 seconds. The weapon required some distance between the point of launch and the front line, as its resupply needs made it vulnerable to enemy attack. This meant that the first strike was critical, as an incomplete attack would compromise its position.

The weapon fired a large assortment of rocket types including smoke projectors, incendiaries, and chemical weapons, making it one of the most psychologically destructive weapons on the battlefields of World War II.

A unique take on rocket launching systems, the XM70 used a revolving chamber to load, fire and discharge rockets. The revolving function of the firing chamber meant that the launcher utilized a single tube, similar to field artillery weapon systems. Previous rocket launchers allowed for rocket exhaust to exit the rear of the firing platform, but the XM70 employed a closed breach and a hydraulic recoil mechanism to compensate for this. As a result, crew members did not need to maintain distance from the firing platform. It also meant that the crew could aim individual rockets, aim more rapidly and readily reload. The XM70 also had longer arms in its split trail, similar to howitzers. Additional benefits included increased accuracy, lower weight, mobility, and better visibility.

Exhaust from rockets fired from previous rocket launchers gave away allied positions. This was negated by laying down heavy rocket fire on enemy positions in the hopes of destroying any potential counter attack. The XM70's employment of a closed breach eliminated this problem.

Rockets fired from the XM70 were fin-stabilized and spun on firing to improve accuracy. This is evident from the rifling within the barrel.

Only seven of these rocket launchers were produced, with a self-propelled variant proposed but never built. The project was cancelled in 1963 due to advancements in field artillery systems and the deployment of smaller, faster surface-to-surface missile systems.

The launcher displayed at Memorial Field is serial number 5 and was made at Rock Island Arsenal in June of 1961.

Designed and developed during World War II, the M5 combined the strengths of multiple weapon systems and consolidated them into one package capable of effectively decommissioning enemy tanks. The gun barrel was repurposed from the T9 anti-aircraft gun, while its internal mechanisms and carriage were borrowed from the M2 howitzer. Mated to an M6 carriage, the gun was designed to replace the smaller, lighter and obsolete M3 37-mm gun, which was not able to mount meaningful resistance against Axis tanks.

The M5 was issued exclusively to tank destroyer battalions. As its nomenclature suggests, its primary use was to destroy enemy tanks at distances of up to nine miles. The M5 saw action in the Italian Campaign, as well as in operations in Northwest Europe.

The M5 entered production in late 1942, with subsequent runs of upgraded variants in 1943 and 1944. The M6 carriage was standardized in November 1943. By the time the guns reached the front lines, most had been refitted with the upgraded M6 carriage. With the larger caliber came heavier weight. By the time the war ended in Europe in 1945, the U.S. Army recognized that the M5 was far too heavy and cumbersome to maneuver in the field. As a result, the M5 was retired in favor of lighter options. Rock Island Arsenal produced 1,650 M9 recoil mechanisms and 1,085 M9A1 recoil mechanisms for this system. The recoil mechanism for the M5 antitank gun displayed at Memorial Field was manufactured at Rock Island Arsenal in 1943.

Today, the M5 is largely maintained as a battery gun used for ceremonial salutes.

The T66 and T66E2 multiple rocket launchers were designed to fire 4.5-in diameter rockets. Produced near the end of World War II, these systems were deployed in limited quantities before the war ended. Multiple revisions to this system were produced, with the 24-tube version named the Honeycomb. There were 15- and 60-tube versions as well, with the largest being called the Hornet's Nest.

The T66 used two different types of rockets during its service life: The M8 and the M16. The M8 was the first rocket used in the T66, with service during World War II. The M16 entered service just two months before the war ended, and all T66 tubes were fitted for this rocket by the onset of the Korean War. Each rocket was unguided, had a solid fuel supply, and weighed around 43 lbs.

The T66 variant applied to the first 206 weapon systems, while the T66E2 variant applied to the next 294. Several improvements were made on the T66E2, including an improved elevating mechanism, a blackout lighting system, a new lunette, a redesigned utility box to house the blackout lighting system, a redesigned conductor cable that was about 50 feet in length, redesigned contact fingers and holding assembly, and a different sight.

The progression of missile and field artillery technology after the Korean War made the Honeycomb and other rocket launchers obsolete by 1954.

The T27E1 is one of 12 rocket launchers designed to fire the M8 self-propelled, fin-stabilized rocket. The T27 and T27E1 were all eight-tube designs, with the T27E2 having 24 tubes. Nicknamed the Xylophone because of its shape and design, the T27 was small enough to be carried in the back of a two-and-a-half ton truck. Despite its light weight, it was difficult to maneuver due to its elongated tubes. As a result a revision, designated the T27E1, was produced.

The T27E1 could be broken down into pieces for easier stowage. It was also easier to reposition on the battlefield, making it more lethal that the T27.

The rockets were first developed in 1941 and entered service in 1943, and were classified as barrage rockets, to be launched in large quantities. Over 2.5 million M8 rockets were produced between 1941 and 1944. Due to the M8's ineffectiveness in striking and damaging armored targets, it was retired before the end World War II, and replaced with the more improved spin-stabilized M16 rocket.

With the development of larger capacity rocket launchers, better rockets, and more accurate and lethal artillery weapons, the T27 was retired at the end of World War II. Other 4.5-in launchers remained in service through the Vietnam War in a limited capacity.

Built with the intention of destroying German tanks, the "Quick Firing" six pounder (QF-6) was a British anti-tank gun. Designed in 1940, the weapon system was designed to be a lightweight, armor-piercing system capable of being deployed in a large number of roles. Due to production issues, it did not enter service until the beginning of the North African Campaign in 1942. The American-produced M1 began production in early 1942, with the more heavily modified and upgraded version (the M1A2) entering production later that year.

By 1943, the U.S. began to favor the M1A2 over the smaller 37-mm M3 gun. Despite initial reluctance to include the weapon in Army inventory, the M1 became standard issue by May 1944. During the invasion of Normandy that June, the U.S. was equipped with Mark II and III revisions of the British QF-6, with the majority of M1s positioned elsewhere on the western front.

The M1 itself was capable of firing an assortment of shells and artillery rounds. Many of these shells were armor piercing, allowing the M1 to effectively fulfill its role as an anti-tank weapon. However, it also fired smaller high-explosive and incendiary shells, which made it a viable field artillery component. The M1 variant saw a great number of exported operators due to the Lend-Lease program, with many units being sent to France and the Soviet Union.

The QF-6 and M1 remained in limited operation up through the 1970s, when it saw its last use during the 1971 war between India and Pakistan.

Designed to be deployed with airborne troops, the M3 105-mm howitzer is a modified version of the smaller 75-mm pack howitzer. The design cannibalized the older M2 howitzer and used the barrel and split trail carriage of the 75-mm pack howitzer. The original design produced for testing in 1941 was designated as the T7. It was not until 1943 that the howitzer entered production as the M3A1. This variant included a reinforced split trail design with thicker metal. The prime mover was typically a standard quarter-ton jeep.

Ahead of the D-Day invasion, some divisions were equipped with the M3A1, while others retained the 75-mm pack howitzer. It was not until December 1944 that the M3A1 entered full service with the Allied Forces, and only by the end of the war did it see service with all airborne divisions in Europe. Other operators of the M3 acquired them through Lend-Lease, including France and the United Kingdom.

While the M3 was retired by the end of World War II by the U.S. Army, some units utilized a modified M3A2 variant during the Korean War. The last operational use was in 1951 by divisions of the Republic of Korea. The M3A2 was equipped with a small shield bracing the barrel to add protection for the fire crew.

Today, M3A1 howitzers are generally used in salute batteries firing blank shells.

Designed to complement and later replace the M53 self-propelled 155-mm gun, the M55 is a 203-mm variant based on the Patton tank. Fitted with 25 millimeters of armor, the M55 was designed to protect the crew from indirect artillery shells, small arms fire, and radioactive fallout. The armor was designed to be light enough so it would not impede the speed of the traversing vehicle, but strong enough to withstand enemy fire.

The M55 was built on the same platform as the M53 gun. The only difference between the two systems was the size and length of the barrel.

The M55 was designed and manufactured by the Pacific Car and Foundry Company. Production began in the 1950s, with the first systems deployed at the end of the Korean War. The howitzer saw its first real action during the Vietnam War, and continued in service until 1969. The howitzer weighed a hefty 48.5 tons, allowing it to easily make its way through heavy brush and dense forests.

By the 1970s, the howitzer had become obsolete. It began to slowly be replaced with the M107 self-propelled howitzer. Some units in Belgium continued to use the howitzer in a limited capacity through 1975, when all M55s were replaced by the M107 or M110 weapon systems.

Developed by the Soviet Union for use on the front lines, the BMP-1 was designed to protect combatants from nuclear radiation, chemical and biological weapons, and conventional rounds. "BMP" stands for Boyevaya Mashina Pekhoty, Russian for "infantry fighting vehicle."

Weighing over 14 tons, the BMP-1 features rolled steel armor that is 33 millimeters thick. It is armed with a 73-mm semi-automatic gun and a 7.62-mm machine gun. It is also equipped with a single Sagger missile mounted above the gun barrel. The combination of armament and weapons allows the BMP-1 to both carry its eight passengers safely to their destination and provide additional close support.

More than 40,000 BMP-1 units were produced, with some exported to more than a dozen Soviet proxy states. Production of the BMP-1 began during the Vietnam War, but it was not until the Yom Kippur War in 1973 that the system was tested in live combat. Both Egyptian and Syrian armed forces used the BMP-1.

Immediately following that war, it was decided that a revision to the BMP-1 was necessary to make it more effective in a rapidly changing battlefield. This led to the development of the BMP-2. The Soviet Army produced a BMP-3 model, a heavily upgraded variant, in 1987.

Due to the low cost to upgrade the systems built into the BMP-1, it remains in service in large quantities around the world. Operators include China, India, Iran, Iraq and Vietnam. Most recently, the BMP-1 has been used in the Syrian Civil War. BMP-1s are also active in Afghanistan and have been deployed in limited numbers against the Taliban.

First tested by the U.S. Army in the 1950s, the MGR-1 (Medium Guided Rocket) Honest John was the first rocket capable of carrying an atomic payload. The rocket itself was designated XM31 during the testing phase, with the X being dropped when the rocket entered its main production sequence and service in 1953.

The Honest John system was designed to fulfill multiple roles on the battlefield. The payload bay was capable of carrying a high-explosive warhead, a cluster bomb, or an atomic device. The high-explosive warhead weighed about 1,500 lbs. The W31 nuclear device was adjustable, having preset yields of 2, 10, or 30 kilotons of explosive power. The cluster bomb consisted of 356 M139 bomblets which were capable of delivering high concentrations of chemicals, such as Sarin nerve agent. The rockets were never equipped with chemical munitions in a live setting.

The weapon system entered large-scale implementation among NATO nations in the late 1950s through the 1960s. By 1968, the larger MGB-1A variant had been phased out in favor of the slightly smaller, lighter and faster MGR-1B. Both variants were deployed across the U.S., Canada, West Germany, Greenland, South Korea and Norway. By the early 1970s, the U.S. began phasing out the Honest John in favor of the smaller and more powerful Lance rocket. By 1991, all U.S.-operated Honest John rockets were removed from the Army inventory.

The Honest John remained in service until 1997, when the last system went offline in South Korea. Other operators had used the system until earlier in the 1990s.

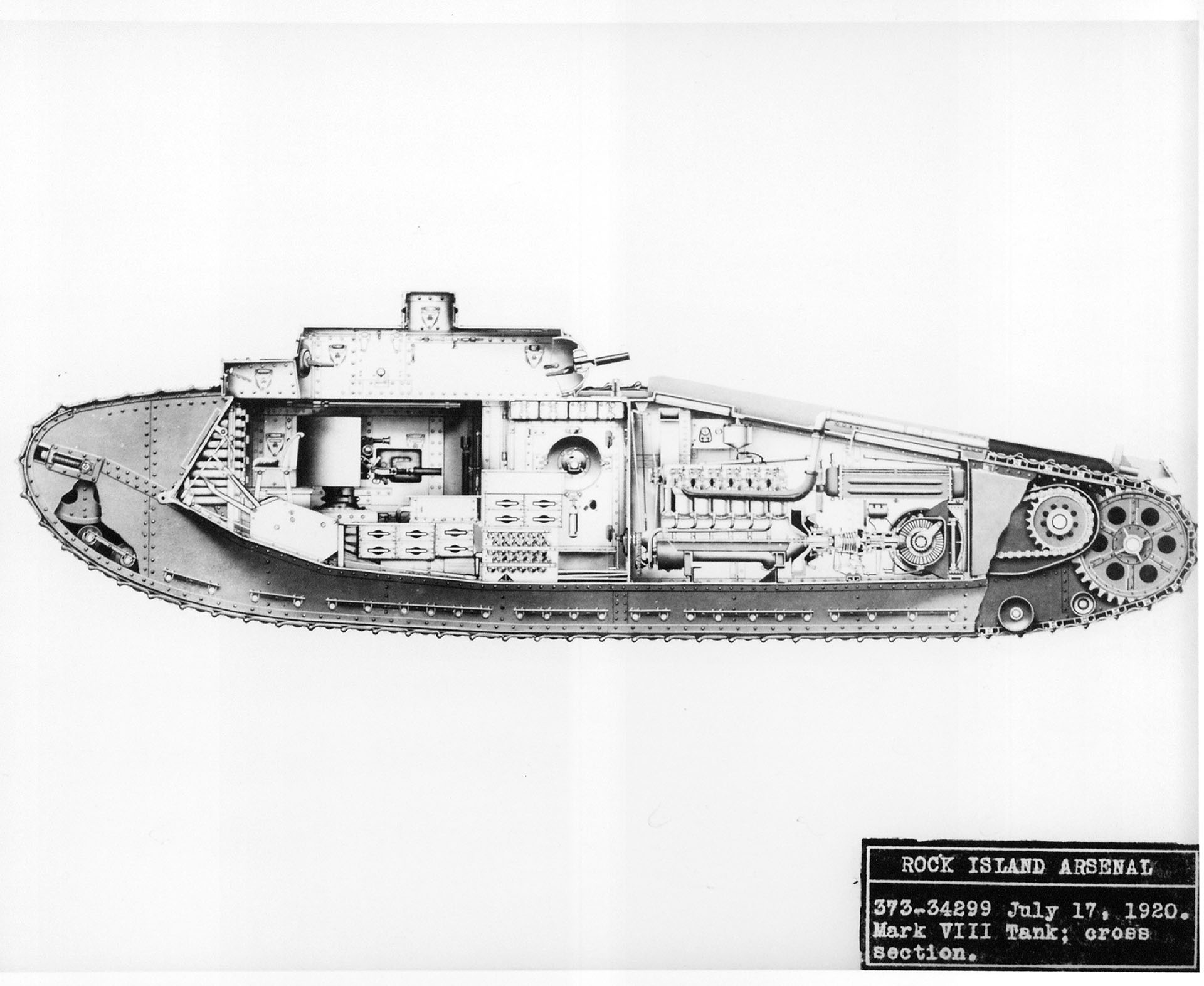

| Mark VIII Tank |

Click on an image to view a larger version

Click on the image above to view the interior of the Mark VIII.

Interactive experience coming soon. |

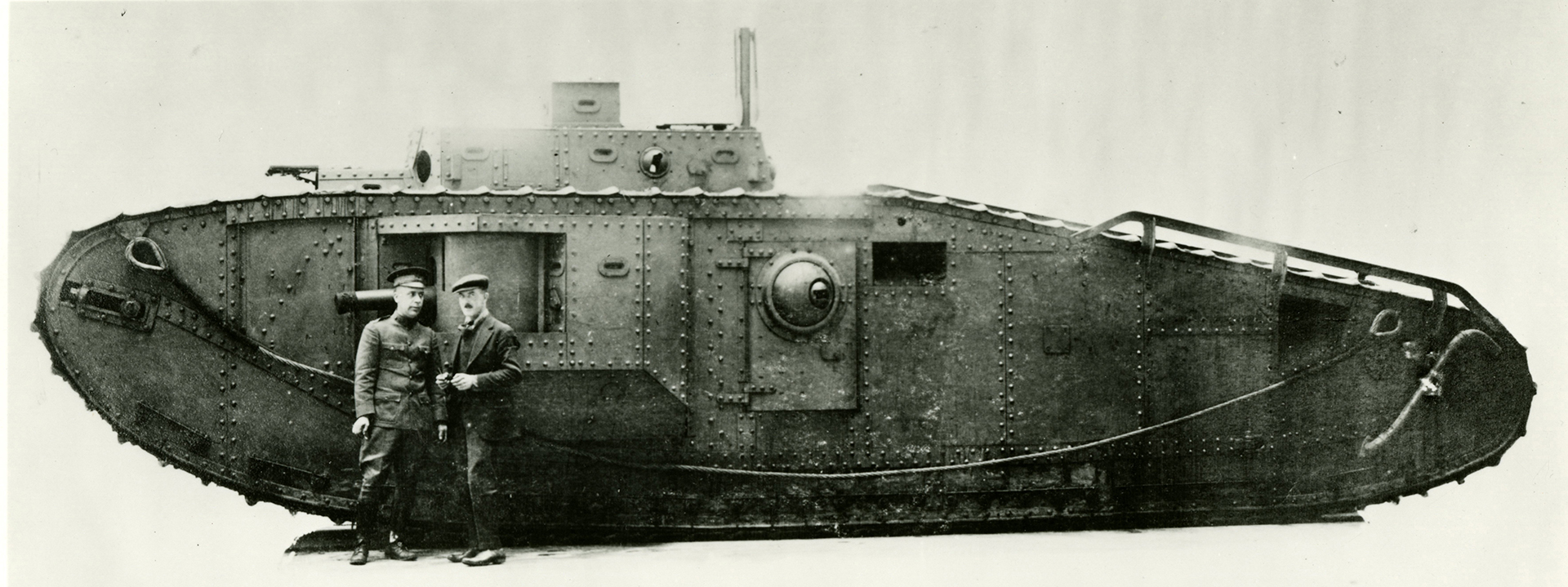

World War I saw the introduction of many technological advancements in weaponry and tactics. Armies were grappling with the introduction of the airplane, machineguns, rapid fire artillery, flame thrower and gas warfare. Chief of these advancements, however, was the tank. The main objective of the tank was to break the stalemate of trench warfare on the western front. Only in this regard, would the Allies be able to drive back the invading German army.

For the Americans, production of a tank of their own did not occur until 1919, during the war Americans used British and French designed tanks. When American production finally began the design was based on the British Mark V design. The American version would be officially labeled the Mark VIII Tank. Weighing about 40 tons with a height of 10 feet, 3 inches, the Mark VIII Tank was nothing short of an industrial marvel. Two 57-mm guns flanked the sides of the tank, with an additional five M1917 Browning machine guns.

The armor and armament made the Mark VIII a perfect weapon of war during campaigns on the western front. However, the other key feature of the tank was its powerful engine and its uniquely shaped tracks. Nicknamed the “Liberty Tank” after its engine, the Mark VIII was capable of sluggish speeds up to five miles per hour utilizing its 300 horsepower Liberty V-12 engine.

The tank was designed to hold a total of eight men, with a driver, an engineer, a commanding officer, and five gunners. Additionally, over 200 rounds of artillery for the 57-mm guns and over 20,000 rounds of ammunitions for the Browning machine guns could be carried in the tank. This reduced the need for resupply while breaking through enemy lines.

The greatest feat, as well as its greatest shortcomings were overcome in the assembly and development stages. The tanks were manufactured in pieces between the United States and Britain during 1919, and then shipped to Rock Island Arsenal for assembly in the Spring.

The Rock Island Arsenal had already been operating at war capacity since before the United States entered World War I, and the order for assembly of 100 of these monolithic tanks was the largest order to date. It is during assembly that the most difficult obstacles in this tank’s production would be met and overcome.

Assembly at the Rock Island Arsenal began on 1 JUL 1919 and took approximately 286 days to complete. The last Mark VIII tank assembled at Rock Island Arsenal was completed and ready for drive testing on 5 JUN 1920. 100 of the total 125 tanks built were assembled at this arsenal. The other 25 were assembled in Britain by the North British Locomotive Company.

The armor and armament were supplied by Britain, with the Browning machine guns being supplied from British inventory. The transmission and engine were supplied by contractors in the United States. Virtually all the parts were then sent to Rock Island Arsenal for assembly.

Problems arose during the assembly process due to different countries supplying parts for one body. Fittings and dimensions needed to be adjusted to correctly assemble the parts onto the body proper without compromising the design or integrity of the tank.

Rock Island Arsenal workers over-came the obstacles and organizational woes associated with the Mark VIII, and successfully turned out the full order. Even as the war died down and ended, the demand for tanks remained high, keeping workers at the arsenal well into the inter war period.

The completed Mark VIII tanks that were produced by the Rock Island Arsenal would remain in the United States active inventory until 1932. Few tanks remain on display today, with their size being the biggest obstacle in the retention. None of these tanks ever saw combat, with the majority being used for training purposes. All but three have since been decommissioned, with only two being American produced (the other is a British specimen). Around 100 years after the tank left the arsenal, one of these two remaining RIA Mark VIII tanks arrived back at the arsenal on 10 MAY 2021. This tank arrived from Fort Benning and was overhauled at the Rock Island Arsenal Joint Manufacturing & Technology Center. It serves as an example of the arsenal’s ability to overcome obstacles in engineering and development.

The other fully restored RIA Mark VIII tank is at Fort Meade, Maryland. The British specimen is at the Bovington Tank Museum and can occasionally be seen operating on the tank track. Today the Mark VIII tank lives on largely only in stories, histories, and pictures. However, it is a permanent reminder of the history of the Rock Island Arsenal. |

| » Fact Sheet « | » More Stories « |

The Rodman series of gun was developed by then- Lieutenant Thomas J. Rodman, who designed them to be used for seacoast fortification. There were five different sizes of bore that were developed for use, measuring 8, 10, 13, 15, and 20 inches. Rodman's design allowed the gun and cast to cool from the inside out, allowing the gun to maintain its structural integrity. Guns up to this point were cooled from the outside in, resulting in tension that would compromise the gun as it was fired repeatedly.

When tested against other weapons, the Rodman Gun was fired 1,500 times. The similar caliber gun that used the older method of cooling was fired 299 times before it was rendered useless. These results continued to show themselves when using inferior materials. Rodman's gun was able to sustain 250 shots, while the counterpart was rendered useless after only 19 rounds. With the success of these tests, the War Department authorized Rodman to cast larger guns with a similar design in 1860.

The 15-inch Rodman Gun was 15.83 feet long, with a bore length of 13.8 feet. It had a bottle-shaped appearance, which made the diameter at its widest point about four feet. It was designed to fire two types of ammunition: Solid shot (which was 450 pounds.) and exploding rounds (330 pounds, with a 17-pound explosive charge).

Almost 2,000 Rodman Guns were produced between 1861 and 1871. Nearly 200 remain today, including three (two 10-inch guns, and one 15-inch gun) that flank General Rodman's grave on Rock Island Arsenal.